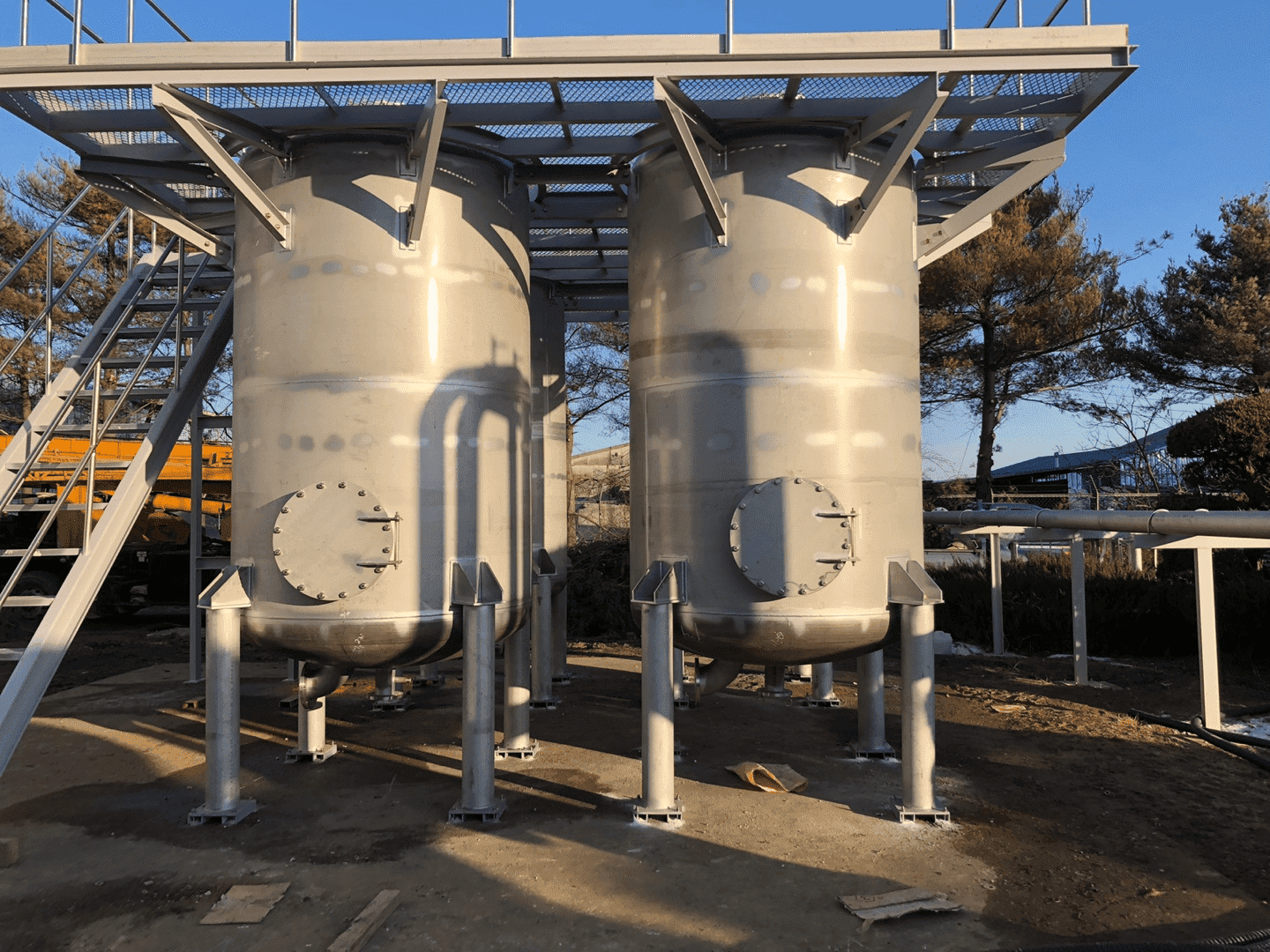

Iksan Sewage Treatment Plant

1. Applied technology/product: pretreatment facility and desulfurization agent2. Flow: 13,200 m3/day3. Inflow condition: hydrogen sulfide concentration 800ppm4. Outflow conditions: hydrogen sulfide concentration 0.01ppm5. Performance standard: hydrogen sulfide concentration 20ppm or less6. Desulfurization tower size (m3): 5 x 2ea (Desulfurization), 4 x 2ea (Desiloxane)7. Remarks: 1) Transfer to drying facility 2) Space velocity: 110hr-1 (desulfurization), 137.5hr-1 (desiloxane) 3) Replacement cycle : 6 months

2022-11-04