Development of materials and processes derived from recycled waste

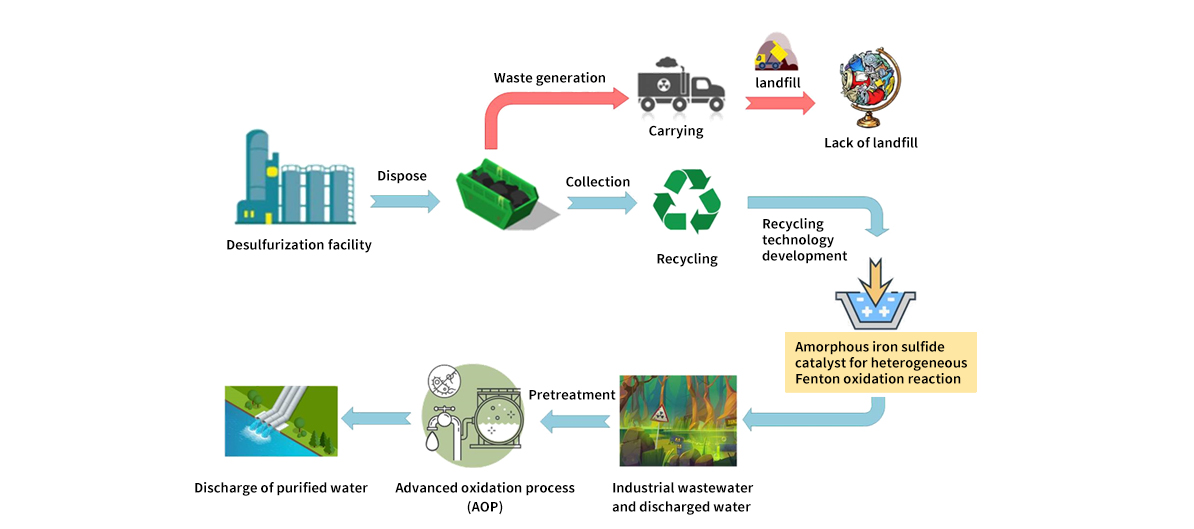

Development of a process to build a resource circulation society by recycling waste desulfurization agent discharged from desulfurization facilities and using it as a Fenton oxidation catalyst for the treatment of hard-to-decompose wastewater.

Introduce

Development of materials and processes derived from recycled waste

Fenton oxidation catalyst overview

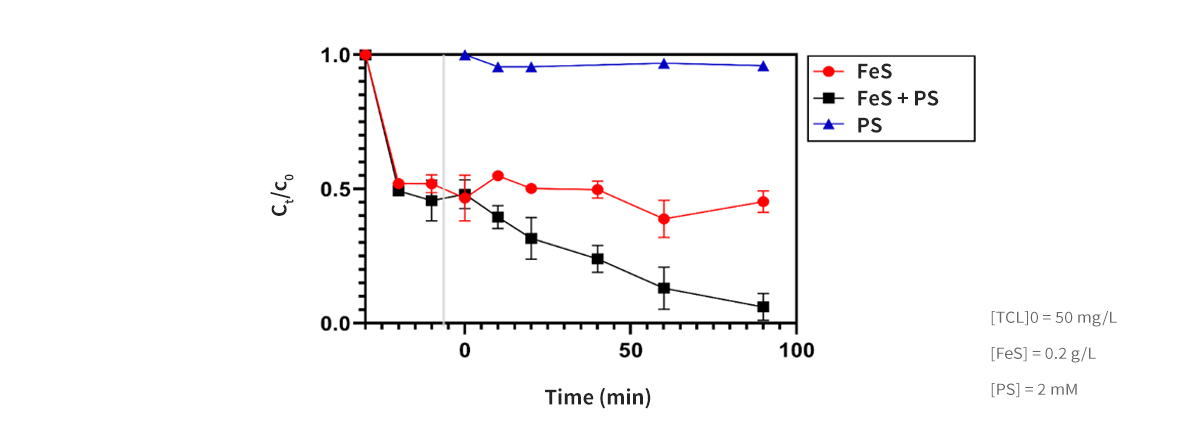

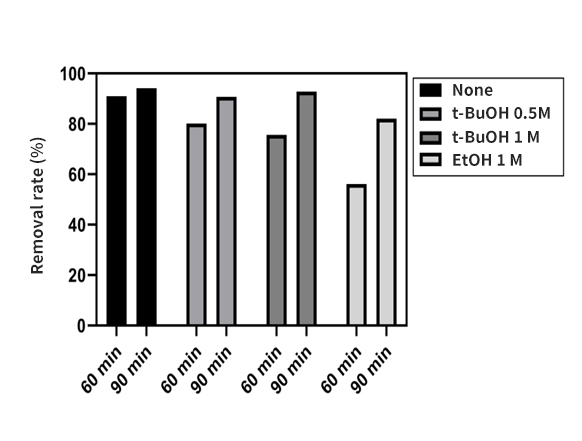

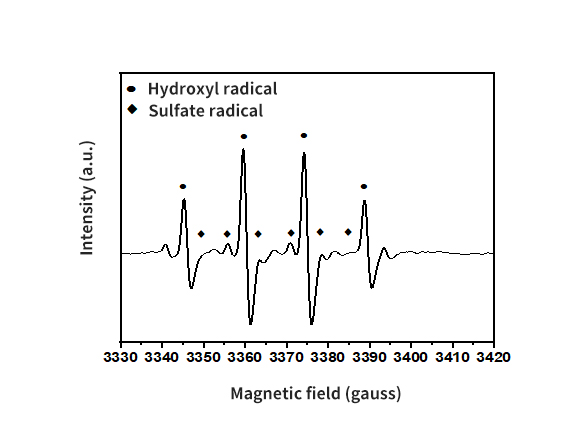

Characteristics of Fenton Oxidation Catalyst

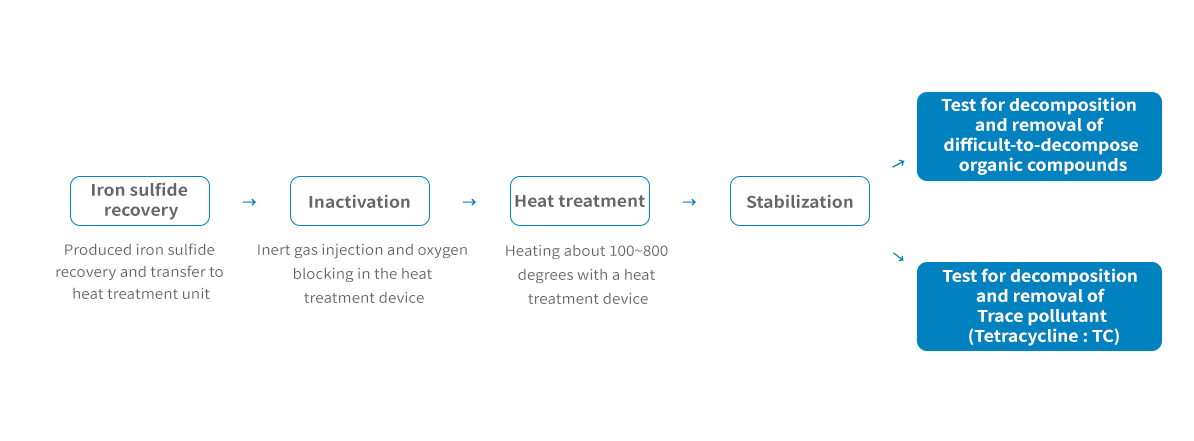

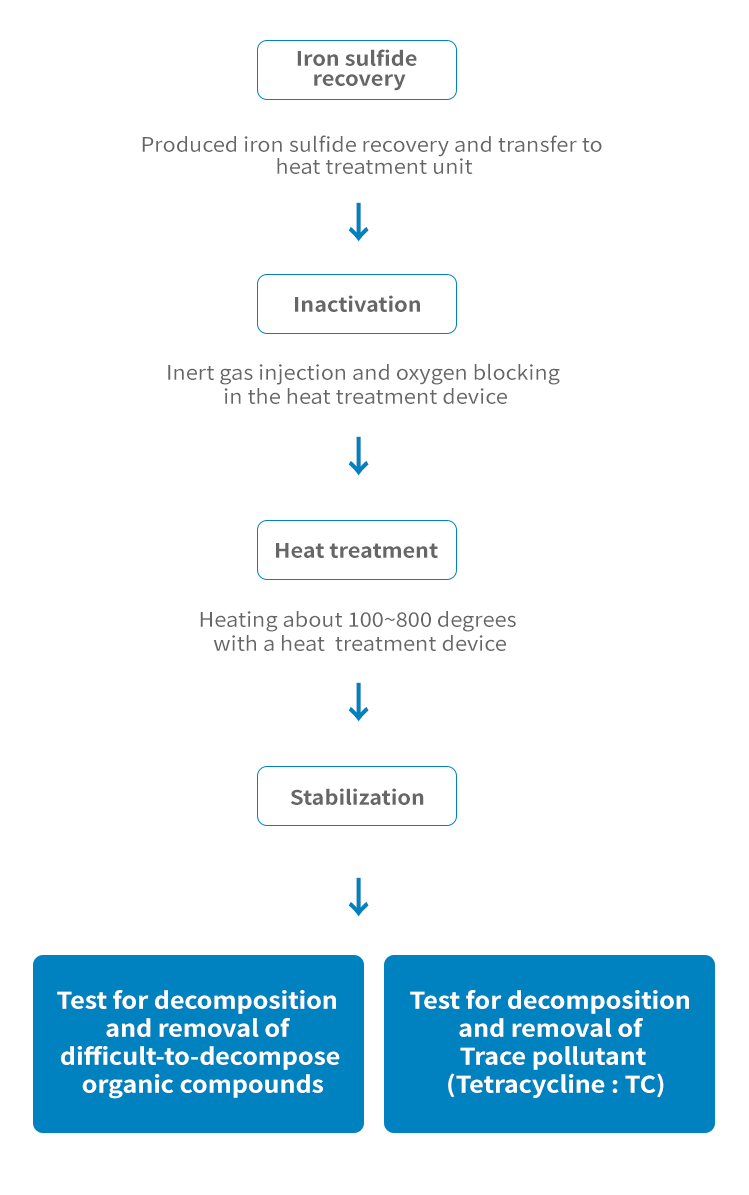

Catalyst production through post-treatment and molding of spent desulfurization agent

Catalyst Manufacturing method